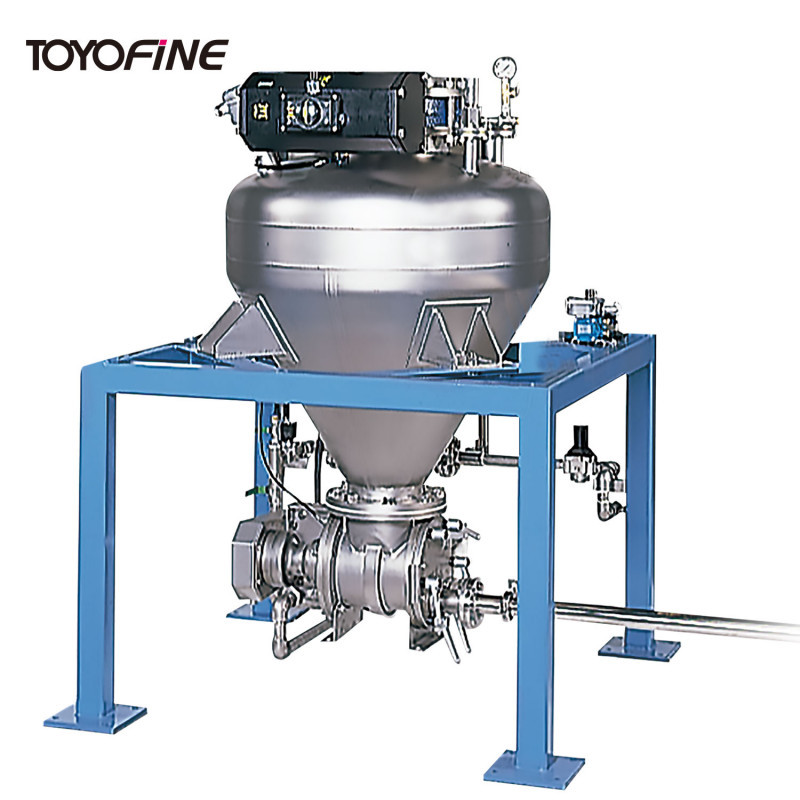

Dense-phase pneumatic conveying system Highpresso (HIP)

High-performance and flexible dense-phase pneumatic conveying system

Features

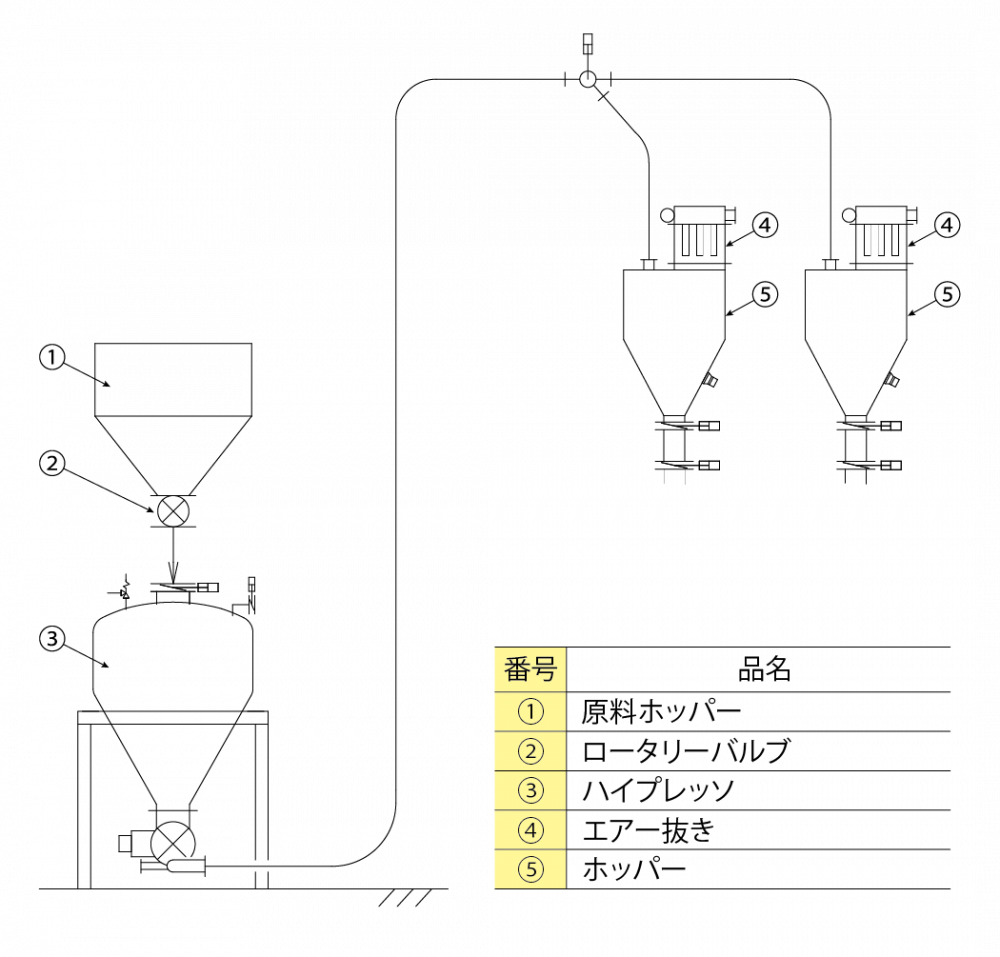

● Stable conveying

Conveying capacity can be easily adjusted by adjusting the feeder speed.

● Stop and restart pneumatic conveying at any time

The use of a rotary feeder allows to stop and restart the pneumatic conveying.

● Optimal conveying conditions can be set

Pressure monitoring and the rotary feeder allow to set the optimal conveying condition.

● Stable pneumatic conveying pressure

Because material propaties don't effect much to the stably feeding conveting, the conveying pressure is stable.

● Good maintenance performanceい

The rotary feeder is sanitary structure for easy cleaning.

Conveying capacity can be easily adjusted by adjusting the feeder speed.

● Stop and restart pneumatic conveying at any time

The use of a rotary feeder allows to stop and restart the pneumatic conveying.

● Optimal conveying conditions can be set

Pressure monitoring and the rotary feeder allow to set the optimal conveying condition.

● Stable pneumatic conveying pressure

Because material propaties don't effect much to the stably feeding conveting, the conveying pressure is stable.

● Good maintenance performanceい

The rotary feeder is sanitary structure for easy cleaning.

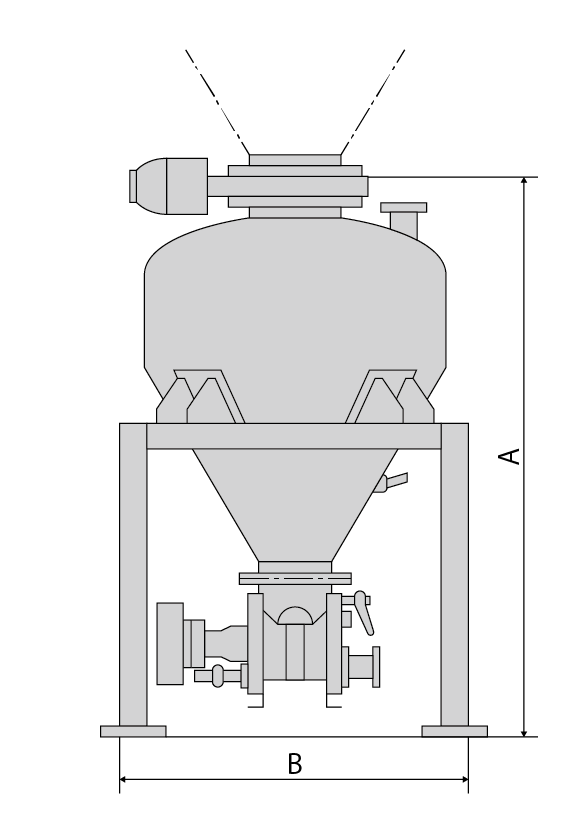

Specifications

| Model | HIP-1B | HIP-2B | HIP-3B |

|---|---|---|---|

| Tank effective capacity(L) | 100 | 300 | 500 |

| Conveying tube diameter | 25A | 50A | 80A |

| Conveying capacity(t/hr) | 0.8~1.4 | 5.0~8.0 | 12.0~18.0 |

| Conveying airflow(㎥/min※) | 0.28~0.48 | 0.90~1.65 | 2.15~3.90 |

| Height(A)mm | 1509 | 1824 | 2138 |

| Width(B)mm | 800 | 1100 | 1350 |

※㎥/min:0℃、101.325kPa

Application examples

| Raw material | Bulk density (g/cm3) | Conveying distance (m) | Airflow(N㎥/min) | Conveying volume (kg/h) |

|---|---|---|---|---|

| Graphite | 0.5 | 40 | 1 | 600 |

| Silica | 0.3 | 90 | 1.5 | 300 |

| Silica | 0.7 | 45 | 1.7 | 5000 |

| Granular product | 0.27 | 85 | 1.5 | 1300 |

| Calcium carbonate | 0.4 | 20 | 3.1 | 1600 |

| Flour | 0.5 | 180 | 2.4 | 600 |

| Granulated sugar | 0.9 | 90 | 1 | 1400 |