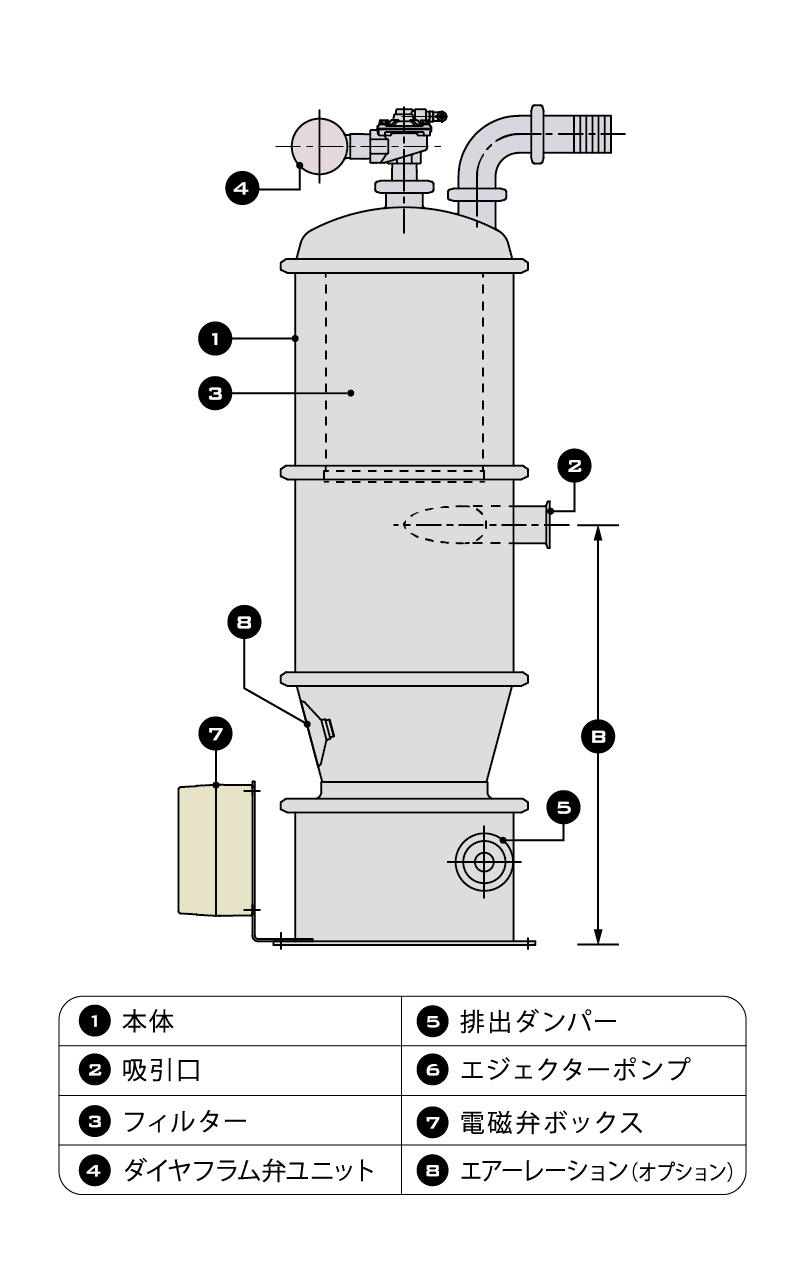

Compact suction-type pneumatic conveying system (Aspec)

Compact pneumatic conveying system with superior sanitary performance

Features

● Compact design

A compact design that has been extremely simplified

● Extremely easy to cleaning

Can be disassembled and reassembled without any tools! Easy to cleaning.

Filter replacement is a one-step operation.

● Reducing powder leakage

Double filter structure reduces the risk of powder leakage.

● Smooth discharge

Large discharge port allows powder to be smoothly discharged.

● Can be explosion-proof specification.

Can be installed in explosion-proofing areas.

● Various types

We offer a various size from small to large scale.

● Lower running costs

Blower type systems to be able to greatly reduce the running costs.

● Including continuous Aspec models

Continuous suction are also available.

A compact design that has been extremely simplified

● Extremely easy to cleaning

Can be disassembled and reassembled without any tools! Easy to cleaning.

Filter replacement is a one-step operation.

● Reducing powder leakage

Double filter structure reduces the risk of powder leakage.

● Smooth discharge

Large discharge port allows powder to be smoothly discharged.

● Can be explosion-proof specification.

Can be installed in explosion-proofing areas.

● Various types

We offer a various size from small to large scale.

● Lower running costs

Blower type systems to be able to greatly reduce the running costs.

● Including continuous Aspec models

Continuous suction are also available.

Specifications

| Model | 250VSX-S | 1000V(L) | 3000V(L) |

|---|---|---|---|

| Conveying capacity (kg/h) | ~150 | ~1000 | ~3000 |

| Suction type | Vacuum pump type | Vacuum pump type | Vacuum pump type |

| Vacuum pump capacity | 1.5㎥/min×-25kPa | -50kPa | -45kPa |

| Motor capacity(kw) | 2.05 | 2.55 | 6.3(VVVF) |

| Air consumption | 2~5L/min | 2~5L/min | 2~5L/min |

| Compressed air supply pressure (kPa) | ~200 | ~200(EX~100) | ~200 |

| Module height (mm) | 454 | 140/280 | 280/430 |

| Equipment maximum height (mm) | 846 | 1149 | 1327 |

| Hopper effective capacity (L) | 6 | 10~40 | 45~75 |

| Nozzle diameter IDF (mm) = Inner diameter | 1.5S=φ35.7 | 2S=φ47.8 | 3S=φ72.3 |

| [Spring-type primary filter] Filter surface area (㎡) | 0.24 | 0.44 | |

| [Secondary standard Axtar] Filter surface area (m2) | 0.85 | 2.68 | |

| [Spring-type primary filter + Secondary standard Axtar] Filter length (mm) | 315 | 325 | |

| [Special Axtar filter] Filter surface area (m2) | 0.79 | 1.39 | 2.68 |

| [Special Axtar filter] Filter length (mm) | 190 | 3030 | 325 |

| [Excel Filter] Filter surface area (m2) | 0.46 | ||

| [Excel Filter] Filter length (mm) | 308 | ||

| System weight (kg) | 18 | 37 | 50 |

Material in Powder contacted parts → Standard: SUS304, inner/outer surface buff #320 (Electropolishing is also available.) / Option: Production using SUS316L is also available.

Application examples

| Raw material | Model | Bulk density(g/㎤) | Conveying distance(m) | Tube inner diameter (φ mm) | Conveying volume(kg/h) |

|---|---|---|---|---|---|

| Carbon | P-1000VL | 0.4 | 15 | 50 | 1000 |

| Lithium carbonate | P-1000VL | 0.45 | 15 | 50 | 500 |

| Manganese dioxide | P-1000VL | 1.58 | 12 | 50 | 1300 |

| Nickel hydroxide | P-1000VL-AX | 0.53 | 25 | 50 | 500 |

| Graphite | P-1000VL | 0.58 | 10 | 50 | 1200 |

| Instant coffee | P-1000VL | 0.3 | 15 | 50 | 1200 |

| Cocoa powder | P-1000VL | 0.4 | 10 | 50 | 700 |

| Creaming powder | P-1000E | 0.35 | 10 | 50 | 1200 |

| Powdered soup | P-1000VL | 0.3 | 15 | 50 | 1200 |

| Food additive | P-1000VL | 0.43 | 16 | 50 | 500 |

| Seasoning | P-1000VL | 0.6 | 20 | 50 | 500 |

| Refined salt | P-3000VL | 1.22 | 20 | 75 | 4000 |

| Toner | P-1000VL-AX(special) | 0.3 | 60 | 50 | 1180 |

| Polyester pellets | P-1000EL | 0.58 | 10 | 50 | 1000 |

| Resin pellets | P-1000EL-AX | 0.6 | 30 | 50 | 800 |

| PE wax powder | P-1000VL | 0.59 | 10 | 50 | 400 |

| Foamed film (sponge) | P-1000VL | 0.13 | 15 | 50 | 600 |

| Resin powder | P-1000VL-AX | 0.74 | 15 | 50 | 500 |

| Acrylic resin powder | P-1000VL-EX | 0.42 | 50 | 50 | 1000 |

| PVA | P-3000VL | 0.57 | 20 | 75 | 3000 |

| Powder fire extinguishing agent | P-1000VL-AX | 1.05 | 15 | 50 | 350 |

| Powder fire extinguishing agent | P-1000VL-AX | 1 | 25 | 50 | 1400 |

| Pharmaceutical intermediate | P-1000VL | 0.7 | 5 | 50 | 1000 |