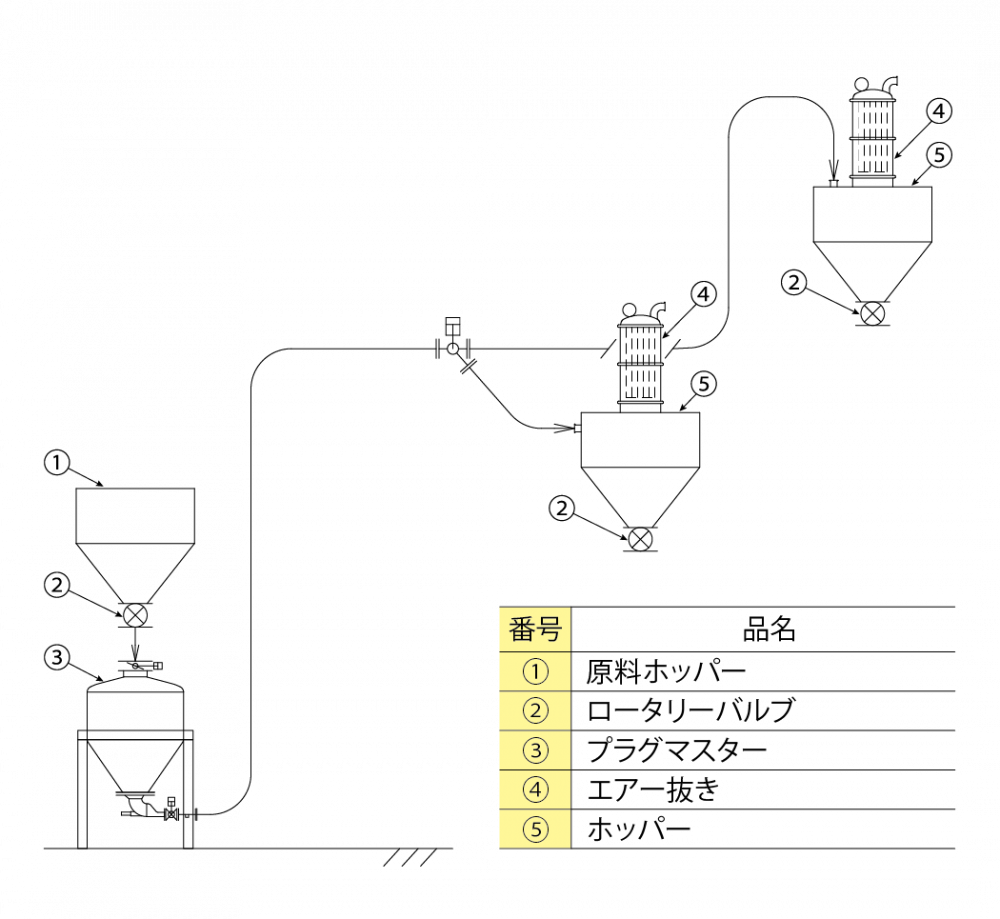

Dense-phase pneumatic conveying system Plug Master (TPM)

It achieves simple and a small air flow Dense-phase pneumatic transportation.

Features

● Reduced damage to raw materials

Because the conveying speed is low, less damage to the raw materials during pneumatic conveying.

● Good maintenance performance

Because the structure is simple, maintenance and cleaning can be easily done.

● Stable conveying

Stable conveying is made possible by means of unique air control with monitoring the pressure.

● Suitable for long distances and large conveying volumes

Many success many cases of successful use for long distances and large conveying volumes. (Tests are also possible.)

Because the conveying speed is low, less damage to the raw materials during pneumatic conveying.

● Good maintenance performance

Because the structure is simple, maintenance and cleaning can be easily done.

● Stable conveying

Stable conveying is made possible by means of unique air control with monitoring the pressure.

● Suitable for long distances and large conveying volumes

Many success many cases of successful use for long distances and large conveying volumes. (Tests are also possible.)

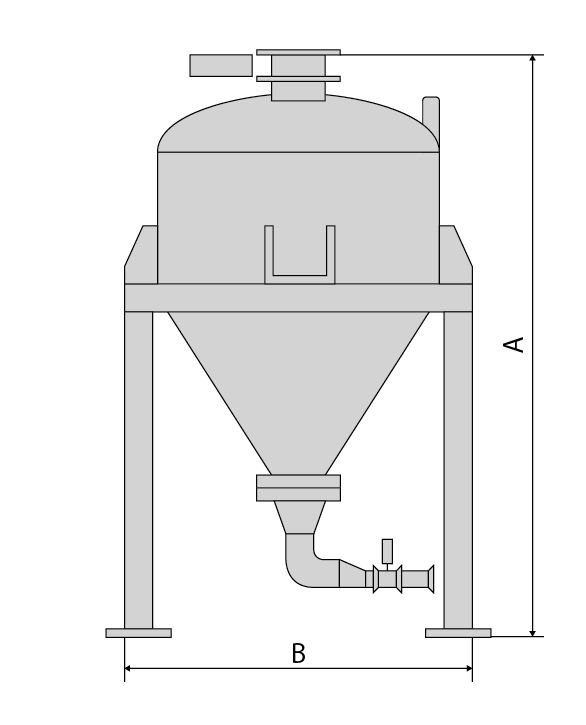

Specifications

| Model | TPM 010-25 | TPM 030-50 | TPM 050-80 | TPM 100-100 |

|---|---|---|---|---|

| Tank effective capacity(L) | 100 | 300 | 500 | 1000 |

| Conveying tube diameter | 25A | 50A | 80A | 100A |

| Conveying capacity(t/hr) | 0.6 | 4.0 | 10.0 | 16.0 |

| Conveying airflow(㎥/min※) | 0.14~0.46 | 0.53~1.70 | 1.21~3.90 | 2.06~6.63 |

| Height(A)mm | 1519 | 1844 | 2184 | 2616 |

| Width(B)mm | 820 | 1200 | 1500 | 1750 |

Application examples

| Raw material | Bulk density (g/cm3) | Conveying distance (m) | Airflow(N㎥/min) | Conveying volume (kg/h) |

|---|---|---|---|---|

| Ternary cathode material | 2 | 15 | 1 | 5000 |

| Ternary cathode material | 1 | 35 | 1 | 3000 |

| Graphite | 0.7 | 15 | 1 | 5000 |

| Graphite | 0.8 | 50 | 1.9 | 7000 |

| Lithium iron phosphate | 0.7 | 35 | 0.7 | 4000 |

| Nickel hydroxide | 1.4 | 300 | 1 | 1000 |

| Lithium nickelate | 2 | 75 | 2.1 | 8000 |

| Lithium carbonate | 0.45 | 27 | 1 | 1400 |

| Electrolyte salt | 1.3 | 15 | 0.8 | 2000 |

| Cathode precursor | 1.2 | 17 | 1 | 500 |

| Anode active material | 0.8 | 65 | 1 | 150 |

| Flour | 0.6 | 90 | 0.6 | 5300 |

| Ground coffee beans | 0.4 | 30 | 0.5 | 3700 |

| Granulated sugar | 0.8 | 40 | 1 | 2300 |

| Refined salt | 1.2 | 110 | 2 | 4700 |

| Granular seasonings | 0.6 | 30 | 0.7 | 2300 |

| Barium sulfate | 1.4 | 90 | 1 | 7200 |

| Pearlite | 0.1 | 50 | 0.5 | 1300 |

| Fire extinguishing agent | 1 | 100 | 1.5 | 3300 |

| Coloring material | 0.6 | 30 | 0.4 | 2700 |