Pneumatic flexible container discharger, type B (PFD-B)

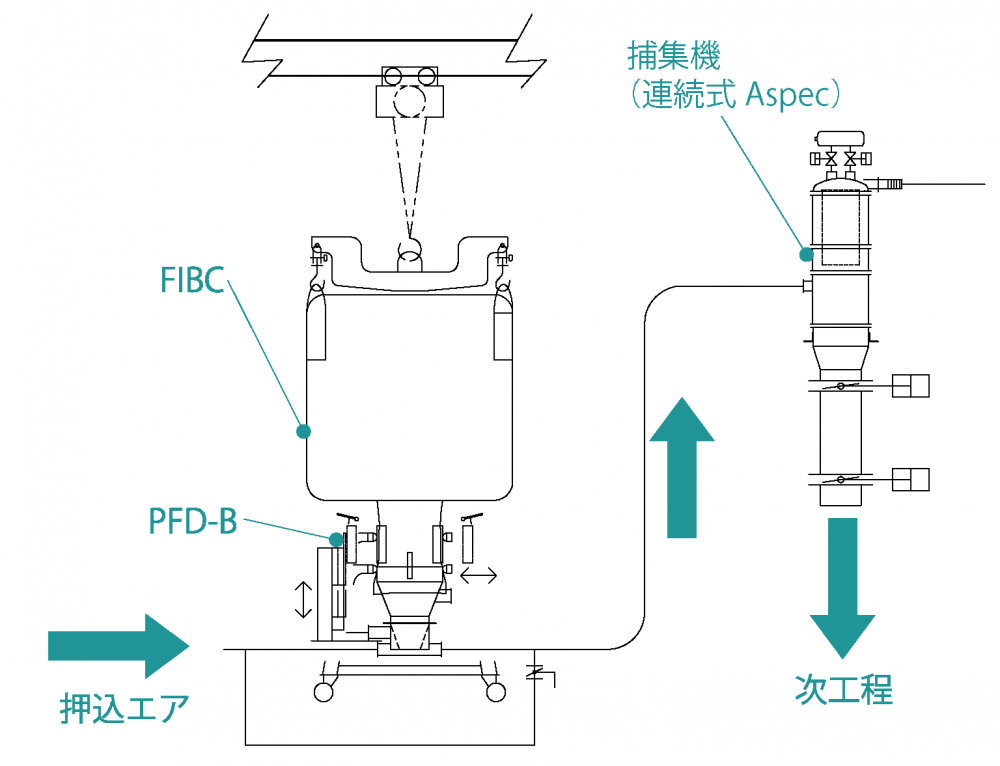

Fully sealed pneumatic conveying system

System for direct conveying from general-purpose flexible intermediate bulk containers (FIBC) with inner bags

Features

● Dust-free discharging and pneumatic conveying from FIBC

Fully sealed system achieves dust-free discharging and pneumatic conveying, making it ideal for color materials and hazardous materials.

● Preventing contamination

Fully sealed operation prevents the intrusion of foreign substances caused by the effects of the external environment.

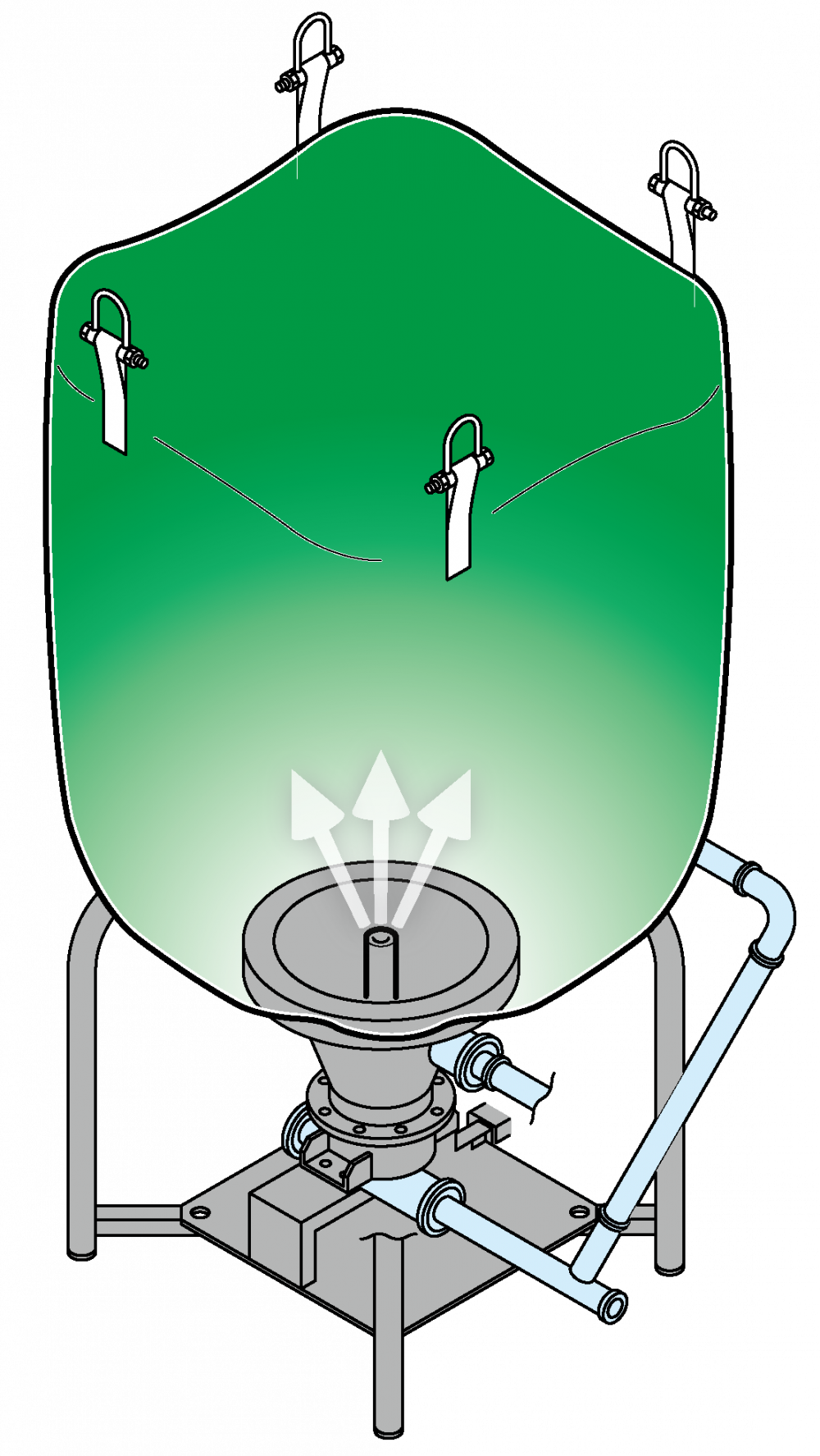

● Also suitable for raw materials with poor fluidity

The special nozzle (option) fluidizes the raw material, improving discharge.

● Reducing residual amount

Expansion and contraction of the FIBC reduces the residual amount that remains in the flexible container (option).

● Labor savings

Capable of pneumatic conveying of raw materials from the FIBC. This simplifies the process and results in an improved work environment.

Fully sealed system achieves dust-free discharging and pneumatic conveying, making it ideal for color materials and hazardous materials.

● Preventing contamination

Fully sealed operation prevents the intrusion of foreign substances caused by the effects of the external environment.

● Also suitable for raw materials with poor fluidity

The special nozzle (option) fluidizes the raw material, improving discharge.

● Reducing residual amount

Expansion and contraction of the FIBC reduces the residual amount that remains in the flexible container (option).

● Labor savings

Capable of pneumatic conveying of raw materials from the FIBC. This simplifies the process and results in an improved work environment.

Movie

Specifications

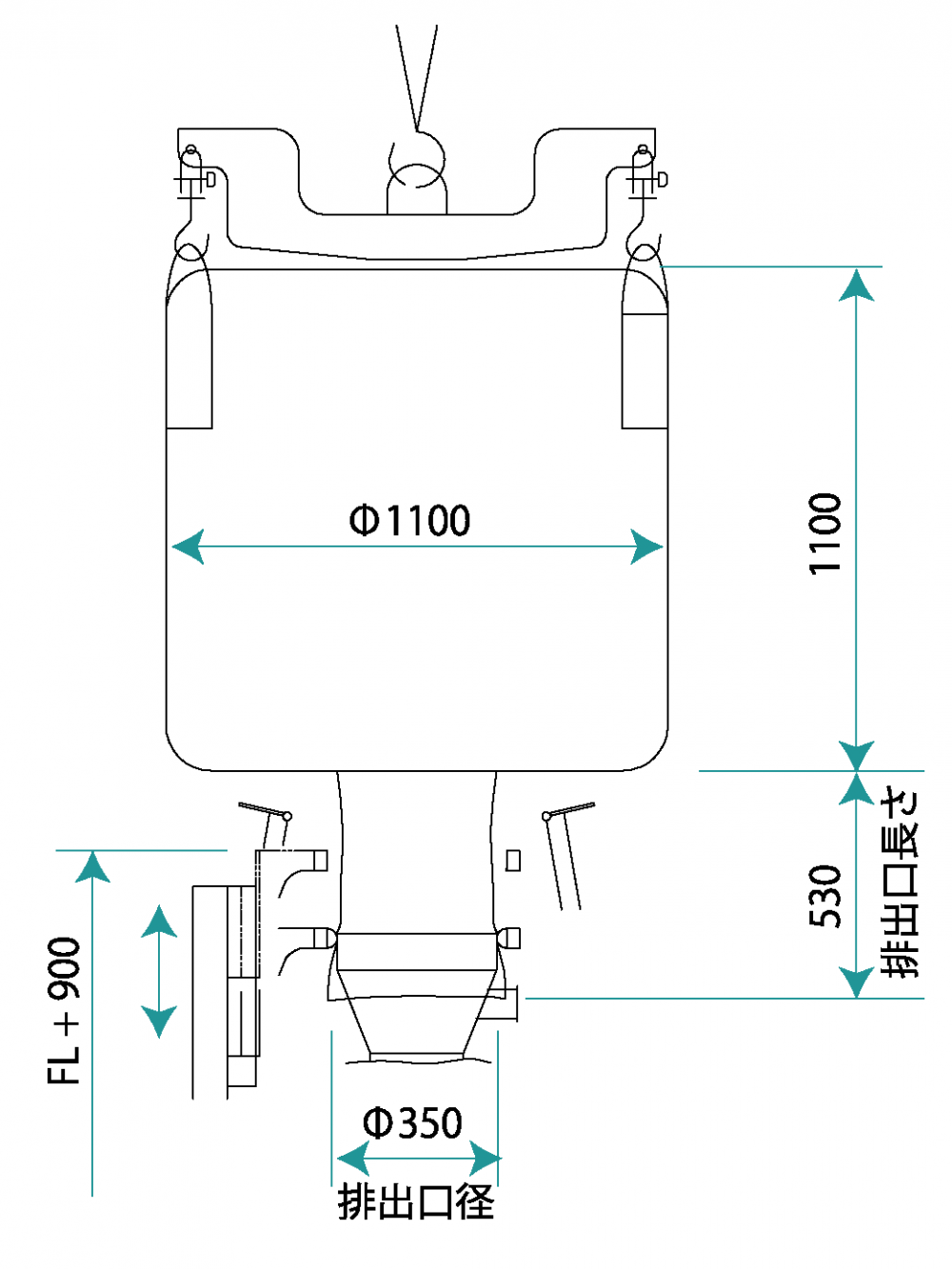

| PFD-B | |

|---|---|

| Conveying capacity | 1500~2000kg/hr (Conveying distance 20~30m) |

| Pneumatic conveying tube diameter | 2.5S |

| Powder contacted material | SUS304 Silicon |

| Discharge port clamp size | φ350 |

| Dimensions(mm) | W1000×D1000×H1000 |

| Weight | 70kg |

| Accessories | Fluidizing nozzle, clamp operation unit, tertiary air operation valve |

| Options | Inner bag expansion prevented clamp, dust collector |

※ Used by connecting with a pneumatic conveying system.

※ Can also be connected with an Aspec compact suction-type pneumatic conveying system (batch or continuous transport).

※ Can also be connected with an Aspec compact suction-type pneumatic conveying system (batch or continuous transport).

Application examples

| Raw material | Bulk density (g/cm3) | Conveying distance (m) | Conveying volume (kg/h) |

|---|---|---|---|

| Graphite | 0.36 | 25 | 675 |

| Talc | 0.41 | 4 | 900 |

| Alumina | 0.53 | 6 | 650 |

| Powdered oil | 0.48 | 10 | 500 |

| Manganese dioxide | 1.2 | 7 | 2000 |

| Carbon | 0.37 | 30 | 1600 |

| Calcium carbonate | 0.86 | 15 | 2700 |

| PVC pellets | 0.84 | 15 | 2500 |