Chacking Master (TCM)

Prevent powder dust in various filling systems.

Features

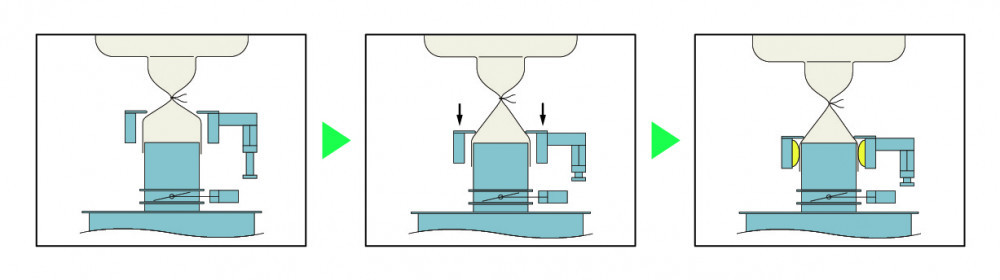

● Prevent powder dust during filling and discharge

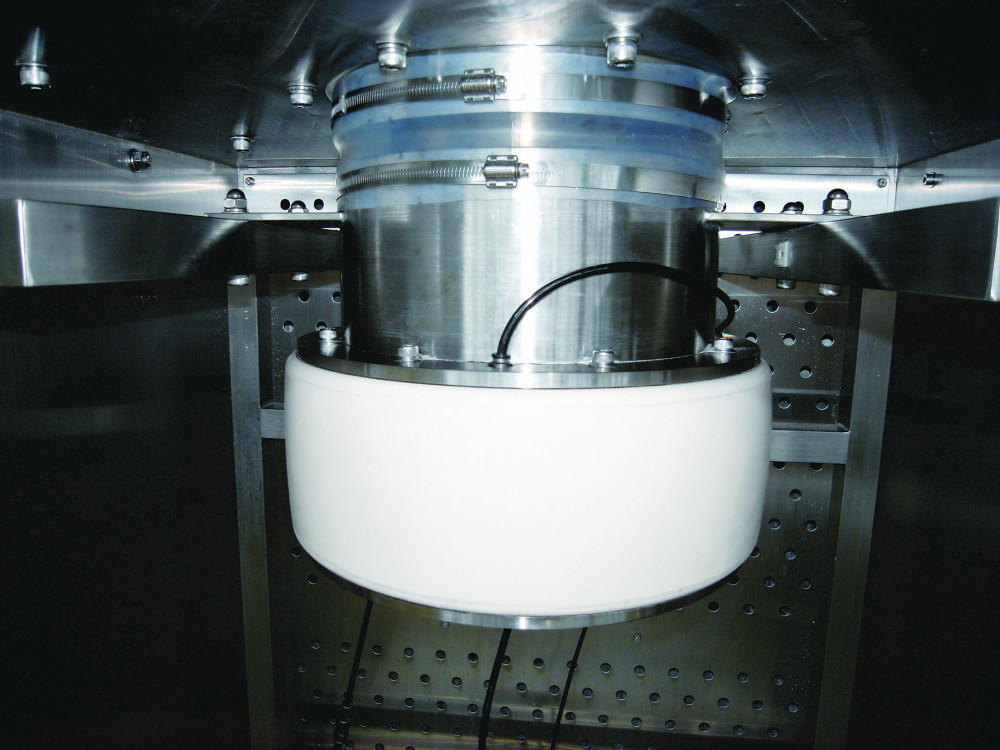

Expansion of the inflatable tube forms a tight seal on various types of bags.

● Easy to work

No tying of the bag or similar work is required, and dust emissions can be prevented with a single touch.

● Less product loss

The raw material feeding pipe has a double structure, and the air adjustment function of the dust collector reduces product loss.

● Various applications

Different variations on lineup and extensive options are available to suit the application.

Expansion of the inflatable tube forms a tight seal on various types of bags.

● Easy to work

No tying of the bag or similar work is required, and dust emissions can be prevented with a single touch.

● Less product loss

The raw material feeding pipe has a double structure, and the air adjustment function of the dust collector reduces product loss.

● Various applications

Different variations on lineup and extensive options are available to suit the application.

Movie

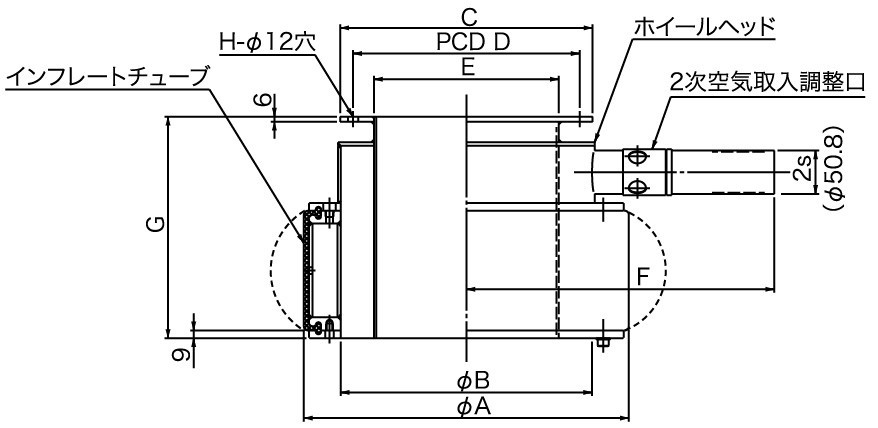

Specifications

| TCM-I | TCM-O | |

|---|---|---|

| Inflator rubber material | High-strength silicon rubber (white) | Model 250: EPDM (black), Model 350: Not decided |

| Operation pressure | ~0.1Mpa | ~0.1Mpa |

| Product touched material | SUS304 | SUS304 |

| Model | Bag size | A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|---|

| TCMI-280 | Φ300~Φ360 | 280 | 200 | 243 | 213 | 150A | 313 | 239 | 6 |

| TCMI-330 | Φ350~Φ410 | 330 | 244 | 295 | 265 | 200A | 335 | 249 | 8 |

| TCMI-380 | Φ400~Φ460 | 380 | 294 | 295 | 265 | 200A | 360 | 259(300) | 8 |

| TCMI-430 | Φ450~Φ510 | 430 | 344 | 295 | 265 | 200A | 385 | 259(300) | 8 |

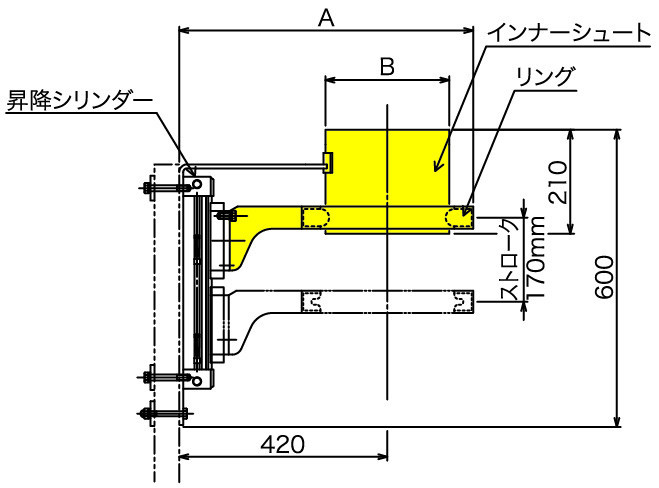

| TCMO-250 | Φ270~Φ370 | 589 | 250 | ー | ー | ー | ー | ー | ー |

| TCMO-350 | Φ370~Φ500 | 639 | 350 | ー | ー | ー | ー | ー | ー |

Application examples

| Raw material | Bulk density (g/cm3) |

|---|---|

| Graphite | 0.2 |

| Ternary cathode material | 2 |

| Negative-electrode active material | 1 |

| Brown sugar | 0.55 |

| Flour | 0.57 |

| Soybean powder | 0.6 |

| Sweetener | 0.87 |

| Instant coffee | 0.3 |

| Cocoa powder | 0.4 |

| Food additive | 0.43 |

| Spices | 0.6 |

| Starch | 0.17 |

| Refined salt | 1.22 |

| Lactose | 0.52 |

| Skim milk powder | 0.61 |

| Granular food | 0.62 |

| Aluminium oxide | 0.53 |

| Plastic powder | 0.5 |

| Toner | 0.3 |

| Acrylic powder | 0.4 |

| PVA | 0.57 |

| Fire extinguishing powder | 1.05 |